Laser cutting OEM - teaching graphic explanation

2021-03-10

In order to let more people understand and use laser cutting, our company has specially written an article to help you quickly understand and how to use it in production. If you already have an understanding of laser cutting, you can click this link "How to "Use laser engraving graphic explanation" to learn more about the use of laser engraving, or select this link "How to use styrofoam cutting graphic explanation" to learn more about the use of styrofoam cutting characters.

If you already have a certain degree of understanding of the use of laser cutting, you can directly click on this link "How to ask for a quotation", provide the relevant information and send an email to our company, you can quickly get a quotation. The quicker the details are).

People who are in contact for the first time often have such troubles. How to use laser cutting? How to use laser cutting to make products? What can laser cutting do? I often meet some new friends or not Friends who are too familiar with laser cutting can’t use this processing correctly, which will cause many problems and unsatisfactory results in production. Therefore, we will write an article on how to use laser cutting to help everyone familiarize with it. If you are already a friend of laser cutting, you can or can add and subtract for reference. Maybe there will be new discoveries. Knowing the usage time of laser cutting can help you get good results in design and production and get twice the result with half the effort.

First of all, what materials can laser cutting cut?

In fact, there are many materials that can be cut, including plywood, dense board, acrylic, stainless steel, PP, cloth, paper, cork... etc. Basically most materials can be cut, because some materials must be cut by laser The light source is processed, so our company currently only introduces the materials that can be processed by our equipment.

Some friends will ask whether some plastic materials like ABS, PVC... etc. can be cut by laser cutting. In fact, it can be cut generally, but because lasers are processed at high temperatures Because of its nature, plastic materials will produce some toxic gas or odor due to the high temperature of laser processing. Therefore, our company will not accept the materials that will produce undesirable substances after laser cutting, so special attention should be paid.

How to use laser cutting

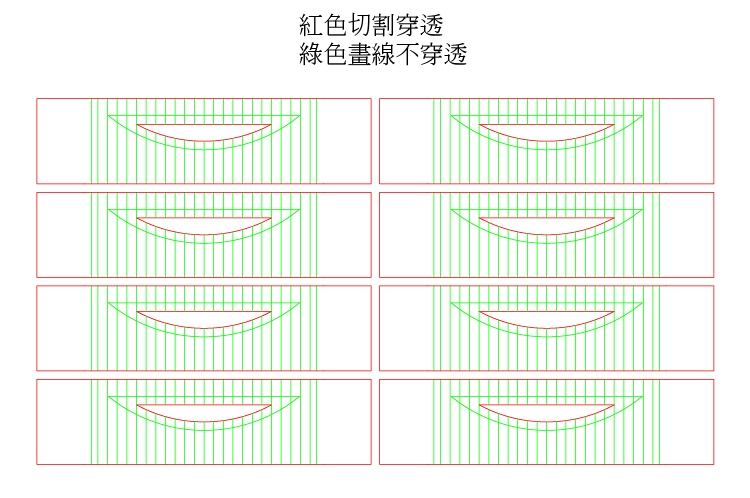

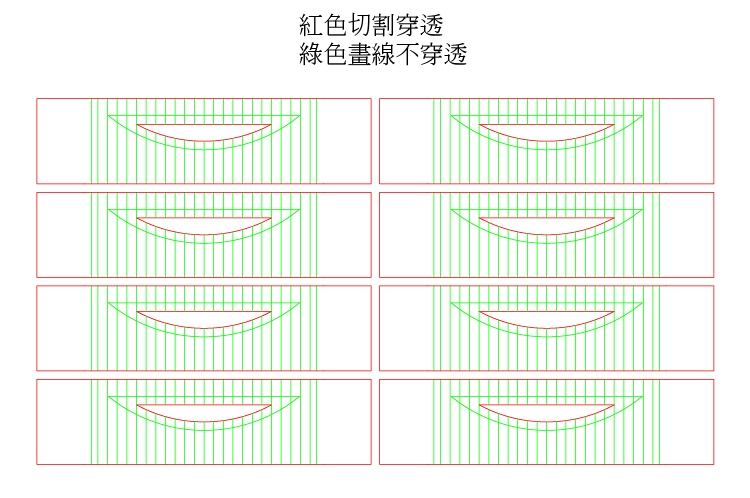

Generally speaking, there are two types of laser cutting parts, one is to cut completely through, and the other is not to penetrate. The following figure illustrates:

This is for the customer to use the plywood to make the model of the ship. The object is cut out by laser cutting and penetrating the required appearance, and the part of the plank pattern on the deck of the ship is presented by laser cutting and marking. , Use the way that the laser marking does not penetrate to show some small details, even if the parts without post-processing are directly combined, it is still very textured. If post-processing is required, the marking can be used as a non-penetrating method. Identify the mark or mark for subsequent assembly, alignment or identification. As long as you understand these two laser cutting methods, you can easily present the feelings and requirements you need.

Precautions for laser cutting image files

The files required for laser cutting must be vector files. Currently, the three most commonly used software on the market are Adobe Illustrator (AI), AUTO CAD (CAD) and Corel Draw (CDR) to draw vector files. If you are using 3D drawing software, you need to first convert the drawing file into a flat engineering drawing, and then output a DXF or DWG file. Some people will ask what a vector file is. Simply put, it is a quantity with a direction and a unit, which means that the length, angle, and direction of a line will be clearly recorded in the file, so the computer can perform laser based on this information. Cutting, the reason why ordinary pictures are not good is because the file recording method is too the same as the dot matrix method, so the computer has no way to cut according to the information of the picture, which is why the vector file relationship is necessary for computer cutting.

Because the laser cutting pricing method is related to the length and complexity of the path you draw, you need to pay attention to some important points when drawing the plan file, which can save you some costs and reduce the risk of failure. The following will explain them one by one.

***

1. Repeat line

Duplicate line is a common problem that everyone encounters. What is a duplicate line is that there are many equal length or shorter line segments hidden in the same straight line, circle or arc. Because laser cutting belongs to computer cutting One type, so although the screen looks like a line when the file is made, the cutting path in the file will be interpreted when the computer is interpreted, and it will be cut truthfully during cutting, which will affect the quality of the cut. Since one of the pricing methods of laser cutting is based on the path length as the pricing benchmark, the number of repetitive lines will affect the obtained price. A small number of repetitive lines may not have much effect, and a large number of repetitive lines may affect the price. The influence of is very obvious, and it is also easy to cause misjudgment by the computer, so it is recommended to check the part of the repeated line first when quoting or laser cutting to avoid unnecessary cost losses.

***

2. How to indicate the penetration and non-penetration of laser cutting on the drawing

If you want to use laser cutting penetration and non-penetration at the same time, how should it be displayed on your drawing? Then you can make good use of the color function in the line type and use the color for the lines of different processing methods. To do the layering, and indicate on the periphery of the drawing which color is used for laser cutting and which color is used for laser cutting and marking. In addition, if you want to include the laser engraving process, this method is also used. Refer to the picture below:

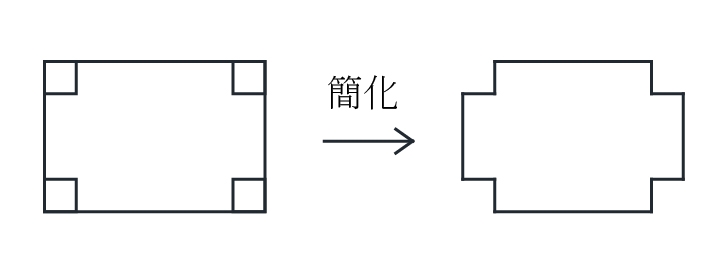

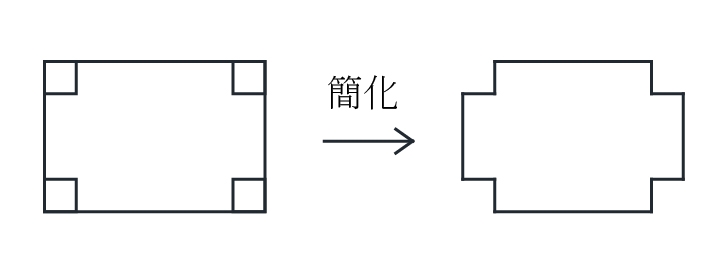

3. Simplification of drawing path of drawing files

Since everyone’s drawing habits of laser cutting diagrams are different, there may be some small problems in the drawing files. Here are a few common small problems, first of all, the simplification of the drawing path. Please refer to the left side of the picture below. Many friends will directly pull the graphics to make the pattern. Although the laser cutting can still be cut, this will cause the four corners to have overlapping lines. In this case, the original object may be caused. The laser cutting has been completed, but because of the overlap line, the dropped object is cut again, which damages the original object, so it is recommended to simplify it to the style on the right side of the figure below.

***

4. How much space should be kept when drawing

Many friends will ask how fine the laser cutting can be, and how much clearance is needed to make the finished product unaffected when drawing. Generally speaking, it will vary according to the material and the thickness of the material, but it is generally recommended The part of non-metallic material should be at least greater than 1mm if it is less than 5mm. If it is greater than 5mm, it is better to maintain a gap of 2mm or more. As for the quality of the metal material, it should run with the thickness of the material. If you choose 1mm metal Material, the minimum retention gap should be greater than 1mm, if 5mm metal material is used, the retention gap should be greater than 5mm. Some people may ask what happens when the gap is smaller than the reserved gap. Basically, if the image file is smaller than the reserved gap during cutting, there is a high chance that it will melt and cause the item to be incomplete and unable to be made. Therefore, the drawing is also Need special attention.

***

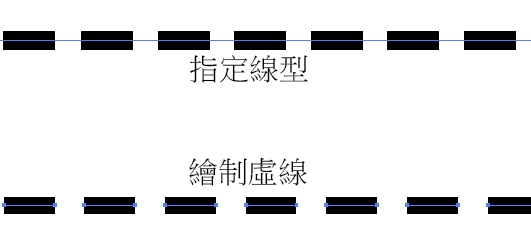

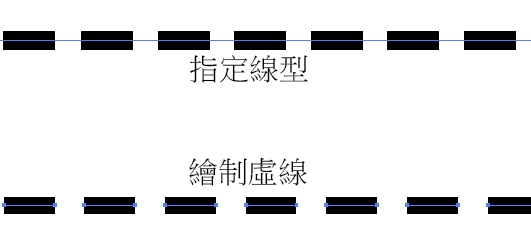

5. Drawing of laser cutting dotted line

Since most software has a line type setting, it is possible to specify the line segment path as a dashed line, but it should be noted that in this case it is displayed for the user, that is to say, the computer displays the dashed line to the user. , But it is actually a straight line in computer interpretation, so if you want to use laser to cut the dashed line segment, you must draw the dashed line segment by segment, so that the computer will only be used for laser cutting. Cut it to the dashed line segment we want. You can refer to the figure below. The upper line uses a line type to specify a dashed line, but in fact the path is still displayed as a line, while the figure below is a redrawn dashed line, and you can see that it is already a section by section.

***

6. Alignment laser cutting

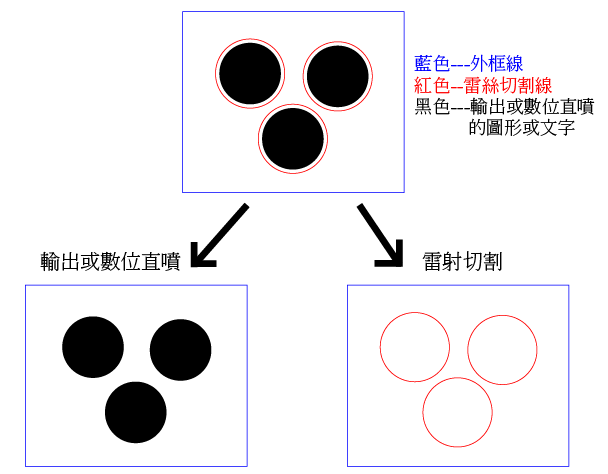

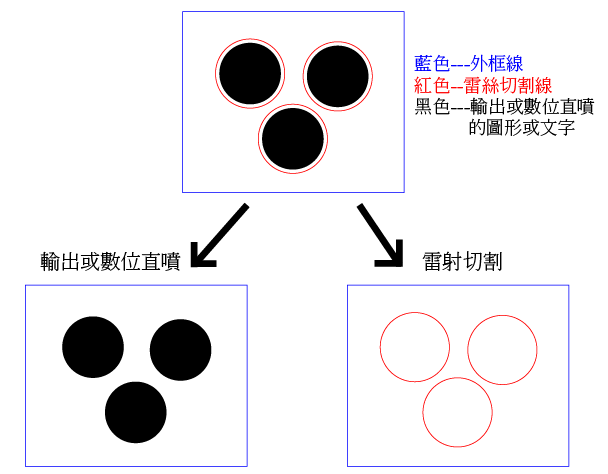

Many people have this kind of sub-demand. Usually, they have already pasted a large image on the board for output or after digital direct printing or direct printing, and they want to cut the printed image. It will be achieved by means of alignment cutting. The following will briefly explain how to deal with the files of alignment laser cutting:

Refer to the figure below. Generally speaking, the output file and the path to be cut will be drawn together in the way above the figure in the production file, but it should be noted that the output or digital direct injection method and laser cutting are separate , So basically the pictures need to be made separately, but only the parts to be laser cut and the parts to be digitally injected or output need to be separated. For the output part as shown in the figure below, you only need to print the required graphic part and one The outer frame line (very important). For the laser cutting part, you only need to provide the laser cutting path and a file of the outer frame line (very important). The outer frame line is a very important part, because the cutting In some cases, a datum point is needed for the alignment part and the relative position of the cutting. Another thing that needs special attention, do not print the laser cutting line when outputting or digital direct injection (very important), Because the alignment is a manual alignment method, there will be deviations to some extent. If the part of the cutting line is printed, it is easy to see the printed cutting line after cutting, so you need to pay special attention to it in use .

7. Section introduction of laser cutting with different materials

Laser cutting can cut a lot of materials, but each material cuts different sections. How do you know the effect of the cutting surface cut by laser? Generally speaking, the cut material will know, or according to Some physical principles are used to speculate the effect, but now there is no need to be so troublesome, our company will sort it out for everyone to consult.

-------------------------------------------------- -

cork

The cork board is made of cork particles and a mixture of high-pressure and high-temperature pressing. Generally, wood is usually black or brown after being cut by laser. In fact, this is the case when the wood is carbonized after the high temperature of the laser. .

-------------------------------------------------- -

Splint

Simply put, plywood is a plank made by pressing several layers of wood, but because it is made by pressing several layers of wood, the wood part in the middle will be different due to different batches of materials. The effect of laser cutting is just Will be different.

-------------------------------------------------- -

Dense board

The dense board is a kind of board that is formed by high-pressure wood chips, so the overall characteristics are relatively stable, and it is very suitable for laser cutting. Because laser cutting will vary in thickness of the board, thicker boards require higher power and are cut. The speed will be slower, so the thicker dense board has a darker cut edge than the thinner dense board.

-------------------------------------------------- -

Acrylic

Acrylic is a commonly used laser cutting material. Laser cutting does not have carbonized black edges like wood. It usually only holds the original color of acrylic, so it is loved by everyone, especially transparent acrylic. Many people will stick colored cards on the front or back to make them, and the brightness and transparency of the acrylic will be quite textured.

-------------------------------------------------- -

EVA foam/PU foam

The above two kinds of foams are generally used as cushioning materials. Generally speaking, EVA is a high-density foam, so it will be harder. PU foam will be softer, and EVA will be more durable than PU. , But the cost of EVA will be higher than that of PU, so it is generally recommended that customers use it according to the actual situation.

-------------------------------------------------- -

-------------------------------------------------- -

Cardboard/paper

Because laser cutting can cut fine and complex patterns, and can basically be formed as long as there are pictures, cardboard cutting is often used in the applications of cartons, architectural models, and cultural and creative products. Compared with a large number of manufacturing processes, The flexibility of the product is quite advantageous in a small amount of production.

More laser cutting displays can be viewed in our product display.

The above information is provided for reference by friends who need it. If the above information cannot solve your needs, you can also directly contact our company.

Articles you may be interested in:

1. "How to know the quotation of laser cutting, laser engraving, styrofoam cutting, CNC cutting"

2. "How to use laser engraving graphic explanation"

If you already have a certain degree of understanding of the use of laser cutting, you can directly click on this link "How to ask for a quotation", provide the relevant information and send an email to our company, you can quickly get a quotation. The quicker the details are).

People who are in contact for the first time often have such troubles. How to use laser cutting? How to use laser cutting to make products? What can laser cutting do? I often meet some new friends or not Friends who are too familiar with laser cutting can’t use this processing correctly, which will cause many problems and unsatisfactory results in production. Therefore, we will write an article on how to use laser cutting to help everyone familiarize with it. If you are already a friend of laser cutting, you can or can add and subtract for reference. Maybe there will be new discoveries. Knowing the usage time of laser cutting can help you get good results in design and production and get twice the result with half the effort.

First of all, what materials can laser cutting cut?

In fact, there are many materials that can be cut, including plywood, dense board, acrylic, stainless steel, PP, cloth, paper, cork... etc. Basically most materials can be cut, because some materials must be cut by laser The light source is processed, so our company currently only introduces the materials that can be processed by our equipment.

Some friends will ask whether some plastic materials like ABS, PVC... etc. can be cut by laser cutting. In fact, it can be cut generally, but because lasers are processed at high temperatures Because of its nature, plastic materials will produce some toxic gas or odor due to the high temperature of laser processing. Therefore, our company will not accept the materials that will produce undesirable substances after laser cutting, so special attention should be paid.

How to use laser cutting

Generally speaking, there are two types of laser cutting parts, one is to cut completely through, and the other is not to penetrate. The following figure illustrates:

This is for the customer to use the plywood to make the model of the ship. The object is cut out by laser cutting and penetrating the required appearance, and the part of the plank pattern on the deck of the ship is presented by laser cutting and marking. , Use the way that the laser marking does not penetrate to show some small details, even if the parts without post-processing are directly combined, it is still very textured. If post-processing is required, the marking can be used as a non-penetrating method. Identify the mark or mark for subsequent assembly, alignment or identification. As long as you understand these two laser cutting methods, you can easily present the feelings and requirements you need.

Precautions for laser cutting image files

The files required for laser cutting must be vector files. Currently, the three most commonly used software on the market are Adobe Illustrator (AI), AUTO CAD (CAD) and Corel Draw (CDR) to draw vector files. If you are using 3D drawing software, you need to first convert the drawing file into a flat engineering drawing, and then output a DXF or DWG file. Some people will ask what a vector file is. Simply put, it is a quantity with a direction and a unit, which means that the length, angle, and direction of a line will be clearly recorded in the file, so the computer can perform laser based on this information. Cutting, the reason why ordinary pictures are not good is because the file recording method is too the same as the dot matrix method, so the computer has no way to cut according to the information of the picture, which is why the vector file relationship is necessary for computer cutting.

Because the laser cutting pricing method is related to the length and complexity of the path you draw, you need to pay attention to some important points when drawing the plan file, which can save you some costs and reduce the risk of failure. The following will explain them one by one.

***

1. Repeat line

Duplicate line is a common problem that everyone encounters. What is a duplicate line is that there are many equal length or shorter line segments hidden in the same straight line, circle or arc. Because laser cutting belongs to computer cutting One type, so although the screen looks like a line when the file is made, the cutting path in the file will be interpreted when the computer is interpreted, and it will be cut truthfully during cutting, which will affect the quality of the cut. Since one of the pricing methods of laser cutting is based on the path length as the pricing benchmark, the number of repetitive lines will affect the obtained price. A small number of repetitive lines may not have much effect, and a large number of repetitive lines may affect the price. The influence of is very obvious, and it is also easy to cause misjudgment by the computer, so it is recommended to check the part of the repeated line first when quoting or laser cutting to avoid unnecessary cost losses.

***

2. How to indicate the penetration and non-penetration of laser cutting on the drawing

If you want to use laser cutting penetration and non-penetration at the same time, how should it be displayed on your drawing? Then you can make good use of the color function in the line type and use the color for the lines of different processing methods. To do the layering, and indicate on the periphery of the drawing which color is used for laser cutting and which color is used for laser cutting and marking. In addition, if you want to include the laser engraving process, this method is also used. Refer to the picture below:

3. Simplification of drawing path of drawing files

Since everyone’s drawing habits of laser cutting diagrams are different, there may be some small problems in the drawing files. Here are a few common small problems, first of all, the simplification of the drawing path. Please refer to the left side of the picture below. Many friends will directly pull the graphics to make the pattern. Although the laser cutting can still be cut, this will cause the four corners to have overlapping lines. In this case, the original object may be caused. The laser cutting has been completed, but because of the overlap line, the dropped object is cut again, which damages the original object, so it is recommended to simplify it to the style on the right side of the figure below.

***

4. How much space should be kept when drawing

Many friends will ask how fine the laser cutting can be, and how much clearance is needed to make the finished product unaffected when drawing. Generally speaking, it will vary according to the material and the thickness of the material, but it is generally recommended The part of non-metallic material should be at least greater than 1mm if it is less than 5mm. If it is greater than 5mm, it is better to maintain a gap of 2mm or more. As for the quality of the metal material, it should run with the thickness of the material. If you choose 1mm metal Material, the minimum retention gap should be greater than 1mm, if 5mm metal material is used, the retention gap should be greater than 5mm. Some people may ask what happens when the gap is smaller than the reserved gap. Basically, if the image file is smaller than the reserved gap during cutting, there is a high chance that it will melt and cause the item to be incomplete and unable to be made. Therefore, the drawing is also Need special attention.

***

5. Drawing of laser cutting dotted line

Since most software has a line type setting, it is possible to specify the line segment path as a dashed line, but it should be noted that in this case it is displayed for the user, that is to say, the computer displays the dashed line to the user. , But it is actually a straight line in computer interpretation, so if you want to use laser to cut the dashed line segment, you must draw the dashed line segment by segment, so that the computer will only be used for laser cutting. Cut it to the dashed line segment we want. You can refer to the figure below. The upper line uses a line type to specify a dashed line, but in fact the path is still displayed as a line, while the figure below is a redrawn dashed line, and you can see that it is already a section by section.

***

6. Alignment laser cutting

Many people have this kind of sub-demand. Usually, they have already pasted a large image on the board for output or after digital direct printing or direct printing, and they want to cut the printed image. It will be achieved by means of alignment cutting. The following will briefly explain how to deal with the files of alignment laser cutting:

Refer to the figure below. Generally speaking, the output file and the path to be cut will be drawn together in the way above the figure in the production file, but it should be noted that the output or digital direct injection method and laser cutting are separate , So basically the pictures need to be made separately, but only the parts to be laser cut and the parts to be digitally injected or output need to be separated. For the output part as shown in the figure below, you only need to print the required graphic part and one The outer frame line (very important). For the laser cutting part, you only need to provide the laser cutting path and a file of the outer frame line (very important). The outer frame line is a very important part, because the cutting In some cases, a datum point is needed for the alignment part and the relative position of the cutting. Another thing that needs special attention, do not print the laser cutting line when outputting or digital direct injection (very important), Because the alignment is a manual alignment method, there will be deviations to some extent. If the part of the cutting line is printed, it is easy to see the printed cutting line after cutting, so you need to pay special attention to it in use .

7. Section introduction of laser cutting with different materials

Laser cutting can cut a lot of materials, but each material cuts different sections. How do you know the effect of the cutting surface cut by laser? Generally speaking, the cut material will know, or according to Some physical principles are used to speculate the effect, but now there is no need to be so troublesome, our company will sort it out for everyone to consult.

-------------------------------------------------- -

cork

The cork board is made of cork particles and a mixture of high-pressure and high-temperature pressing. Generally, wood is usually black or brown after being cut by laser. In fact, this is the case when the wood is carbonized after the high temperature of the laser. .

-------------------------------------------------- -

Splint

Simply put, plywood is a plank made by pressing several layers of wood, but because it is made by pressing several layers of wood, the wood part in the middle will be different due to different batches of materials. The effect of laser cutting is just Will be different.

-------------------------------------------------- -

Dense board

The dense board is a kind of board that is formed by high-pressure wood chips, so the overall characteristics are relatively stable, and it is very suitable for laser cutting. Because laser cutting will vary in thickness of the board, thicker boards require higher power and are cut. The speed will be slower, so the thicker dense board has a darker cut edge than the thinner dense board.

-------------------------------------------------- -

Acrylic

Acrylic is a commonly used laser cutting material. Laser cutting does not have carbonized black edges like wood. It usually only holds the original color of acrylic, so it is loved by everyone, especially transparent acrylic. Many people will stick colored cards on the front or back to make them, and the brightness and transparency of the acrylic will be quite textured.

-------------------------------------------------- -

EVA foam/PU foam

The above two kinds of foams are generally used as cushioning materials. Generally speaking, EVA is a high-density foam, so it will be harder. PU foam will be softer, and EVA will be more durable than PU. , But the cost of EVA will be higher than that of PU, so it is generally recommended that customers use it according to the actual situation.

Cardboard/paper

Because laser cutting can cut fine and complex patterns, and can basically be formed as long as there are pictures, cardboard cutting is often used in the applications of cartons, architectural models, and cultural and creative products. Compared with a large number of manufacturing processes, The flexibility of the product is quite advantageous in a small amount of production.

More laser cutting displays can be viewed in our product display.

The above information is provided for reference by friends who need it. If the above information cannot solve your needs, you can also directly contact our company.

Articles you may be interested in:

1. "How to know the quotation of laser cutting, laser engraving, styrofoam cutting, CNC cutting"

2. "How to use laser engraving graphic explanation"