Laser engraving OEM- teaching graphic explanation

2021-03-16

In order to let more people understand and use laser engraving, our company has written a special article to help you quickly understand and how to use it in production. If you already have an understanding of laser engraving, you can click this link "How to "Use laser cutting graphic explanation" to learn more about the use of laser engraving, or select this link "How to use styrofoam cutting graphic explanation" to learn more about the use of styrofoam cutting characters.

If you already have a certain degree of understanding of the use of laser engraving, you can directly click on this link "How to ask for a quotation", provide the relevant information and send an email to our company, and you can quickly get a quotation. The quicker the details are).

First of all, I will briefly introduce the principle of laser engraving. Simply put, it uses the principle of light focusing to project artificial light on the focusing lens to form a high-temperature and high-energy light spot, and make an instant high-temperature burn on the surface of the object. Burning gasification, so laser engraving is a kind of surface engraving or surface reaction processing, and it cannot be colored on the surface of the object by laser engraving. All the colors presented are based on the object receiving the energy of the laser light. Therefore, our company cannot control the color that appears, so special attention should be paid to the use. If you want to use laser engraving and you are not familiar with how to use it, the following will give you some knowledge and introduction on laser engraving.

1. What files are needed for laser engraving

The difference between laser engraving and laser cutting is that image files can be used. In addition to the original AI, CAD, CDR, image files such as JPG, BMP and other image file formats can also be used, but you need to pay attention to the image files. It is recommended that the resolution be higher, which can reduce the distortion in the computer conversion process. Of course, in addition to engraving photos on the object, it is generally recommended that vector files are the best choice. Some friends will say that if you want to laser engrave some simple text, but they will not use related ones. What about the program? Generally speaking, you can use word to type the characters you need, but the designation of the font may only use the commonly used fonts. If you have multiple different contents, you can use excel to do it. Just make a list.

2. Materials that can be processed by laser engraving

Laser engraving can basically be engraved on any material, stainless steel, wood, acrylic, paper, ceramics and some plastic materials. In fact, there are many kinds of materials. It is worth mentioning that plastic materials are generally just a general term, but there are actually many kinds. And it is usually mixed and used, which leads to the effect of laser engraving is not ideal. Therefore, if laser engraving is required for plastic materials, it is recommended to do proofing before proceeding to mass production. Since there are many kinds of materials, it is generally recommended to send a letter directly to ask questions faster.

3. Precautions for laser engraving image files

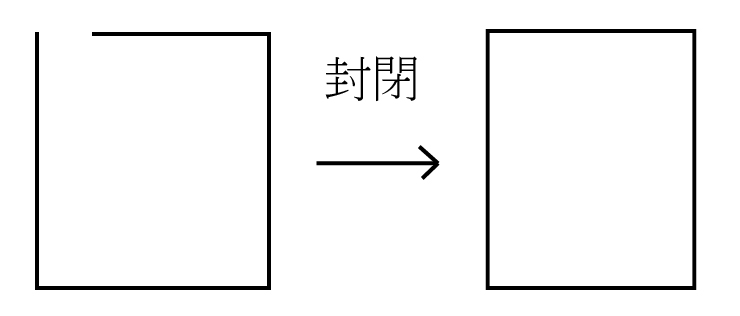

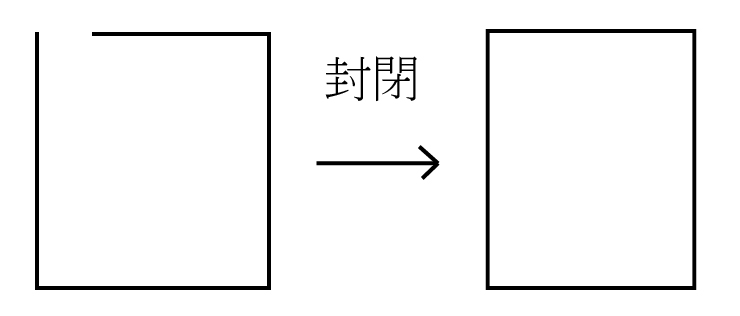

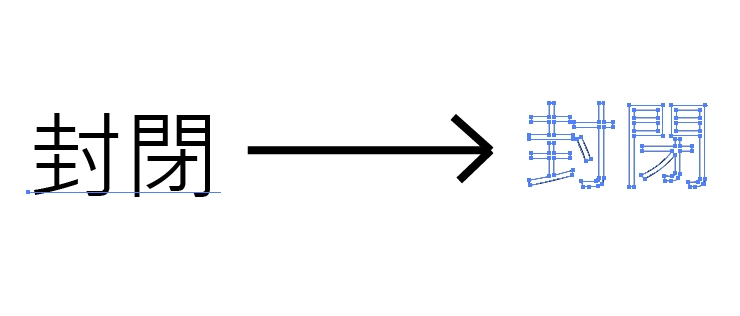

If the laser engraving image file is a vector file, it must basically be a closed line break. What is a closed line break? That is, the head and tail of the line break need to be connected to form a blocked block. There are ways to do filling processing, as shown in the figure below:

In addition, not only laser engraving needs to pay attention to the problem of path closure, but also laser cutting. Since laser cutting will follow the path you describe, if the path is not closed, the laser cutting will be As shown in the picture above, there will also be a gap that is not cut off, which will cause the cut items to not be removed smoothly, so pay special attention to this small detail.

4. The part used in the text font

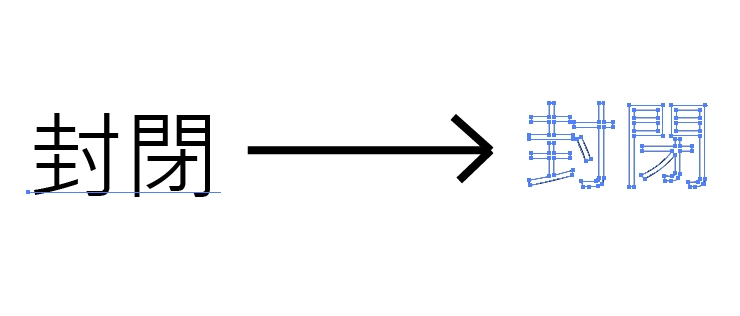

Because the text usually specifies different styles of fonts to meet the required style, but the text does not exist for laser engraving computers. Simply put, the computer only recognizes the line segment path, so if you need to laser engrave the text part It is necessary to go through the part of the outer frame, so that the engraving computer can correctly recognize the content of the image file. Another advantage of the outer frame is that it can prevent the font from running away because of different computers or the computer does not have a corresponding font. AI The software has the function of converting the text frame, but because the CAD part does not have this part, it needs to install a plug-in or convert with different software to achieve this. As shown below:

Not only does laser engraving work like this, if you want to use laser to cut three-dimensional characters, you also need to use this method to convert the text part into a wire frame, so that the machine can correctly identify what you want to make. . In other words, the required pattern is made into a closed block.

In addition, you need to pay special attention to the pattern that needs laser engraving. Like laser cutting, there should be no overlapping lines. If there are overlapping lines, it will cause the computer to misjudge the laser engraving area. Therefore, you need to pay special attention when making graphics files. .

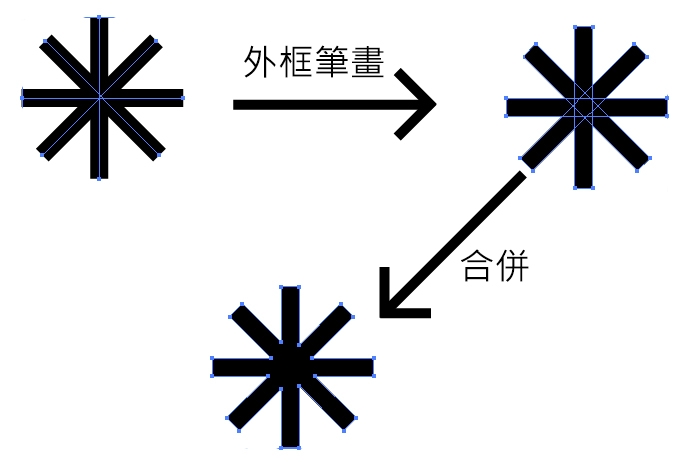

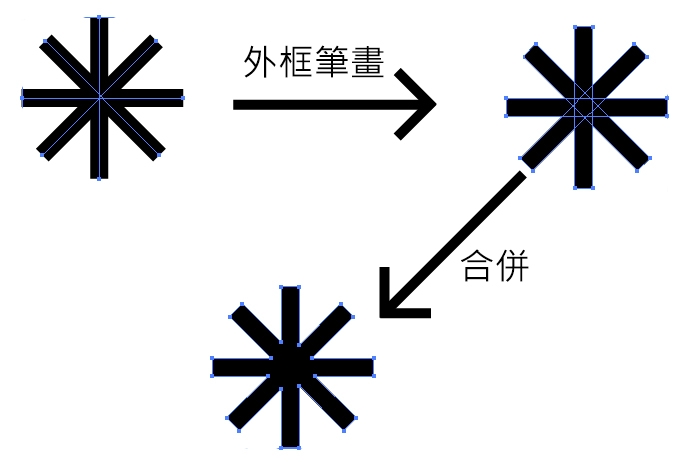

If the figure is constructed with lines and has a specified line width, if you want to engrave the figure by laser engraving, you must convert the line to the stroke of the outer frame. If the line is converted to the stroke of the outer frame, you need to The action of merging graphics is to merge all the outer frame line segments into a graphic outer frame, so that laser engraving can be carried out. You can refer to the following illustration:

6. How to indicate the situation that laser engraving and laser cutting will be used at the same time?

If you will use more than two construction methods, you can use different colors to show them on the drawing. For example: you can preset black for laser cutting, green for laser marking, and red for laser cutting. In the way of shooting and engraving, you can distinguish your graphics with colors for different processes, and indicate them with text in the side part.

7. What is the laser engraving depth? Can the depth be specified?

Some friends will want to engrave a little bit deeper or the part of the specified depth. First discuss the part of the specified depth. Generally speaking, because the laser light belongs to a kind of energy, the same energy will have different depths on different materials. Some The hardness of the material is higher, and the density of some is lower. In this case, the depth will be different, especially the part with annual rings or knots such as logs, which will easily cause the same conditions as the depth of laser engraving. And the effect is not the same. Of course, the effect of laser engraving with more homogeneous materials such as acrylic or dense board will be more uniform.

In addition, the depth part is mentioned by many friends who use laser engraving. Generally speaking, the depth of laser engraving can be deep or shallow, but for this part, it is generally recommended to use it according to the situation, assuming you are on the surface Laser engraving logo is used for recognition. Generally speaking, the effect is enough. If your depth has other effects, such as rubbing molds, seals, etc., it needs a certain depth to function. It is recommended to deepen the depth, and another important point is that the depth part will involve the problem of processing costs, so it is recommended that you first consider your needs when using it.

7. Can I use laser to engrave photos?

Many friends often ask such questions. In fact, it is possible. However, there are many questions that need to be paid attention to. The first is the selection of photos. Generally speaking, because laser engraving photos use the method of spotting Excellent grade, so the darker parts will be densely distributed, and the lighter parts will be sparsely distributed. Therefore, in general, when selecting photos, it is generally recommended to compare photos with a higher contrast, so that the laser engraved The effect will be better, and the other is the resolution and detail issues. These two will be said together because the two will have a positive correlation. Generally speaking, a photo with a higher resolution will have more details. In laser engraving, if you If you want to show more details in the picture, you need to enlarge the size you need. Generally, the size of the output such as a large group photo should not be too small, otherwise the expressions of many characters will not come out. Relatively, if For small objects, it is recommended to choose a single photo as much as possible. If it is a portrait, it is a big-head photo, because small objects have less space to fill in more details, so special attention should be paid to use. In addition, some of the pictures suggest that you need high-resolution pictures to engrave more details.

The effect of laser engraving of various materials

Splint

In general, the front and back of the plywood and the sandwich material are usually not certain, so the effect of laser engraving is not always certain. Some are very deep but some are very light. Unless it is a certain kind of veneer on a certain surface, it will be different. The splint laser engraving effect of the film is not always certain.

Dense board

The material characteristics of the dense board are very stable. The effect of laser engraving is brown. Of course, the deeper the depth, the deeper the color. It is unlikely that the effect of engraving from different plates will be different, so many people like it. Use this material to make products.

Stainless steel

Many products will use stainless steel with brushed surface to show the texture of metal. Stainless steel has a very good effect for laser engraving. Generally speaking, our company has two types of stainless steel engraving. One effect is silver white ( Light carving), the place where the laser has been engraved is silvery white, but the depth of the engraving is very shallow. It can be seen but the depth is hard to be felt. The other effect is brown-black, and the place where the laser has been engraved is darker in color. The place that has passed is more protruding to the touch. The other is to engrave deep (laser deep engraving), which is to use repetition to engrave the surface of the material to reach a certain engraving depth, so this method is more costly. Laser engraving The effect can refer to the figure below.

Painted or electroplated metal

Some metals will be sprayed with a thin layer of paint, and the paint on the surface will be scraped off by laser engraving to reveal the color of the substrate, but there are some things to pay attention to. The first is that the paint is generally to protect the metal surface. It is not oxidized, so if the part of the substrate is rusty or easily oxidized, it is generally not recommended to do laser engraving. If it is really necessary to process, it is recommended to do surface protection work afterwards.

Transparent acrylic

Transparent acrylic is a commonly used material. After laser engraving, the surface appears white, which is quite good in recognition and is often used widely. In addition, acrylic itself has the function of guiding light, so in transparent acrylic After the surface is engraved, there will be a bit of depth, and then it will show a three-dimensional effect after lighting from the side. The above information is provided for your reference.

White acrylic/black acrylic

In addition to transparent acrylic, I will introduce you to black and white acrylic. Different from the previous method of engraving a certain depth on the surface and then applying white or black lacquer, you can now directly use laser engraving. , The black acrylic engraving is directly carved into white, and the white acrylic part is directly carved into gray, so that everyone can have more choices in using acrylic.

Leather leather laser engraving

Under normal circumstances, without other surface treatment, the effect of leather engraving by laser will generally be brown and black. If the surface is dyed or colored, the color after laser engraving may be possible. It will be deeper, but because different leather materials basically have different conditions, the actual processing conditions are still the main.

Articles you may be interested in:

How to know the quotation of laser cutting, laser engraving, styrofoam cutting, CNC cutting

How to use laser cutting graphics

If you already have a certain degree of understanding of the use of laser engraving, you can directly click on this link "How to ask for a quotation", provide the relevant information and send an email to our company, and you can quickly get a quotation. The quicker the details are).

First of all, I will briefly introduce the principle of laser engraving. Simply put, it uses the principle of light focusing to project artificial light on the focusing lens to form a high-temperature and high-energy light spot, and make an instant high-temperature burn on the surface of the object. Burning gasification, so laser engraving is a kind of surface engraving or surface reaction processing, and it cannot be colored on the surface of the object by laser engraving. All the colors presented are based on the object receiving the energy of the laser light. Therefore, our company cannot control the color that appears, so special attention should be paid to the use. If you want to use laser engraving and you are not familiar with how to use it, the following will give you some knowledge and introduction on laser engraving.

1. What files are needed for laser engraving

The difference between laser engraving and laser cutting is that image files can be used. In addition to the original AI, CAD, CDR, image files such as JPG, BMP and other image file formats can also be used, but you need to pay attention to the image files. It is recommended that the resolution be higher, which can reduce the distortion in the computer conversion process. Of course, in addition to engraving photos on the object, it is generally recommended that vector files are the best choice. Some friends will say that if you want to laser engrave some simple text, but they will not use related ones. What about the program? Generally speaking, you can use word to type the characters you need, but the designation of the font may only use the commonly used fonts. If you have multiple different contents, you can use excel to do it. Just make a list.

2. Materials that can be processed by laser engraving

Laser engraving can basically be engraved on any material, stainless steel, wood, acrylic, paper, ceramics and some plastic materials. In fact, there are many kinds of materials. It is worth mentioning that plastic materials are generally just a general term, but there are actually many kinds. And it is usually mixed and used, which leads to the effect of laser engraving is not ideal. Therefore, if laser engraving is required for plastic materials, it is recommended to do proofing before proceeding to mass production. Since there are many kinds of materials, it is generally recommended to send a letter directly to ask questions faster.

3. Precautions for laser engraving image files

If the laser engraving image file is a vector file, it must basically be a closed line break. What is a closed line break? That is, the head and tail of the line break need to be connected to form a blocked block. There are ways to do filling processing, as shown in the figure below:

In addition, not only laser engraving needs to pay attention to the problem of path closure, but also laser cutting. Since laser cutting will follow the path you describe, if the path is not closed, the laser cutting will be As shown in the picture above, there will also be a gap that is not cut off, which will cause the cut items to not be removed smoothly, so pay special attention to this small detail.

4. The part used in the text font

Because the text usually specifies different styles of fonts to meet the required style, but the text does not exist for laser engraving computers. Simply put, the computer only recognizes the line segment path, so if you need to laser engrave the text part It is necessary to go through the part of the outer frame, so that the engraving computer can correctly recognize the content of the image file. Another advantage of the outer frame is that it can prevent the font from running away because of different computers or the computer does not have a corresponding font. AI The software has the function of converting the text frame, but because the CAD part does not have this part, it needs to install a plug-in or convert with different software to achieve this. As shown below:

Not only does laser engraving work like this, if you want to use laser to cut three-dimensional characters, you also need to use this method to convert the text part into a wire frame, so that the machine can correctly identify what you want to make. . In other words, the required pattern is made into a closed block.

In addition, you need to pay special attention to the pattern that needs laser engraving. Like laser cutting, there should be no overlapping lines. If there are overlapping lines, it will cause the computer to misjudge the laser engraving area. Therefore, you need to pay special attention when making graphics files. .

If the figure is constructed with lines and has a specified line width, if you want to engrave the figure by laser engraving, you must convert the line to the stroke of the outer frame. If the line is converted to the stroke of the outer frame, you need to The action of merging graphics is to merge all the outer frame line segments into a graphic outer frame, so that laser engraving can be carried out. You can refer to the following illustration:

6. How to indicate the situation that laser engraving and laser cutting will be used at the same time?

If you will use more than two construction methods, you can use different colors to show them on the drawing. For example: you can preset black for laser cutting, green for laser marking, and red for laser cutting. In the way of shooting and engraving, you can distinguish your graphics with colors for different processes, and indicate them with text in the side part.

7. What is the laser engraving depth? Can the depth be specified?

Some friends will want to engrave a little bit deeper or the part of the specified depth. First discuss the part of the specified depth. Generally speaking, because the laser light belongs to a kind of energy, the same energy will have different depths on different materials. Some The hardness of the material is higher, and the density of some is lower. In this case, the depth will be different, especially the part with annual rings or knots such as logs, which will easily cause the same conditions as the depth of laser engraving. And the effect is not the same. Of course, the effect of laser engraving with more homogeneous materials such as acrylic or dense board will be more uniform.

In addition, the depth part is mentioned by many friends who use laser engraving. Generally speaking, the depth of laser engraving can be deep or shallow, but for this part, it is generally recommended to use it according to the situation, assuming you are on the surface Laser engraving logo is used for recognition. Generally speaking, the effect is enough. If your depth has other effects, such as rubbing molds, seals, etc., it needs a certain depth to function. It is recommended to deepen the depth, and another important point is that the depth part will involve the problem of processing costs, so it is recommended that you first consider your needs when using it.

7. Can I use laser to engrave photos?

Many friends often ask such questions. In fact, it is possible. However, there are many questions that need to be paid attention to. The first is the selection of photos. Generally speaking, because laser engraving photos use the method of spotting Excellent grade, so the darker parts will be densely distributed, and the lighter parts will be sparsely distributed. Therefore, in general, when selecting photos, it is generally recommended to compare photos with a higher contrast, so that the laser engraved The effect will be better, and the other is the resolution and detail issues. These two will be said together because the two will have a positive correlation. Generally speaking, a photo with a higher resolution will have more details. In laser engraving, if you If you want to show more details in the picture, you need to enlarge the size you need. Generally, the size of the output such as a large group photo should not be too small, otherwise the expressions of many characters will not come out. Relatively, if For small objects, it is recommended to choose a single photo as much as possible. If it is a portrait, it is a big-head photo, because small objects have less space to fill in more details, so special attention should be paid to use. In addition, some of the pictures suggest that you need high-resolution pictures to engrave more details.

The effect of laser engraving of various materials

Splint

In general, the front and back of the plywood and the sandwich material are usually not certain, so the effect of laser engraving is not always certain. Some are very deep but some are very light. Unless it is a certain kind of veneer on a certain surface, it will be different. The splint laser engraving effect of the film is not always certain.

Dense board

The material characteristics of the dense board are very stable. The effect of laser engraving is brown. Of course, the deeper the depth, the deeper the color. It is unlikely that the effect of engraving from different plates will be different, so many people like it. Use this material to make products.

Stainless steel

Many products will use stainless steel with brushed surface to show the texture of metal. Stainless steel has a very good effect for laser engraving. Generally speaking, our company has two types of stainless steel engraving. One effect is silver white ( Light carving), the place where the laser has been engraved is silvery white, but the depth of the engraving is very shallow. It can be seen but the depth is hard to be felt. The other effect is brown-black, and the place where the laser has been engraved is darker in color. The place that has passed is more protruding to the touch. The other is to engrave deep (laser deep engraving), which is to use repetition to engrave the surface of the material to reach a certain engraving depth, so this method is more costly. Laser engraving The effect can refer to the figure below.

Painted or electroplated metal

Some metals will be sprayed with a thin layer of paint, and the paint on the surface will be scraped off by laser engraving to reveal the color of the substrate, but there are some things to pay attention to. The first is that the paint is generally to protect the metal surface. It is not oxidized, so if the part of the substrate is rusty or easily oxidized, it is generally not recommended to do laser engraving. If it is really necessary to process, it is recommended to do surface protection work afterwards.

Transparent acrylic

Transparent acrylic is a commonly used material. After laser engraving, the surface appears white, which is quite good in recognition and is often used widely. In addition, acrylic itself has the function of guiding light, so in transparent acrylic After the surface is engraved, there will be a bit of depth, and then it will show a three-dimensional effect after lighting from the side. The above information is provided for your reference.

White acrylic/black acrylic

In addition to transparent acrylic, I will introduce you to black and white acrylic. Different from the previous method of engraving a certain depth on the surface and then applying white or black lacquer, you can now directly use laser engraving. , The black acrylic engraving is directly carved into white, and the white acrylic part is directly carved into gray, so that everyone can have more choices in using acrylic.

Leather leather laser engraving

Under normal circumstances, without other surface treatment, the effect of leather engraving by laser will generally be brown and black. If the surface is dyed or colored, the color after laser engraving may be possible. It will be deeper, but because different leather materials basically have different conditions, the actual processing conditions are still the main.

Articles you may be interested in:

How to know the quotation of laser cutting, laser engraving, styrofoam cutting, CNC cutting

How to use laser cutting graphics